In urgent maintenance jobs, workers may feel pressure to move quickly and restore equipment as fast as possible. This can lead to unsafe decisions, including the idea of skipping the hasp step during lockout/tagout (LOTO).

Skipping a hasp is not just a shortcut — it removes the safety system that protects each person involved. Without individual lock control, someone may reactivate equipment while another person is still working. This puts lives at risk.

Bypassing any part of the LOTO process increases the chance of serious injury, legal action, or even death. The urgency of a repair does not remove the need for proper safety steps.

The only safe option is to follow full LOTO procedures every time. That includes using hasps, even under time pressure. Teams must be trained, prepared, and equipped to lock out energy sources properly, no matter how urgent the job.

Skipping hasps during urgent maintenance is unsafe and non-compliant. This article explains why hasps are critical to LOTO and must be used at all times.

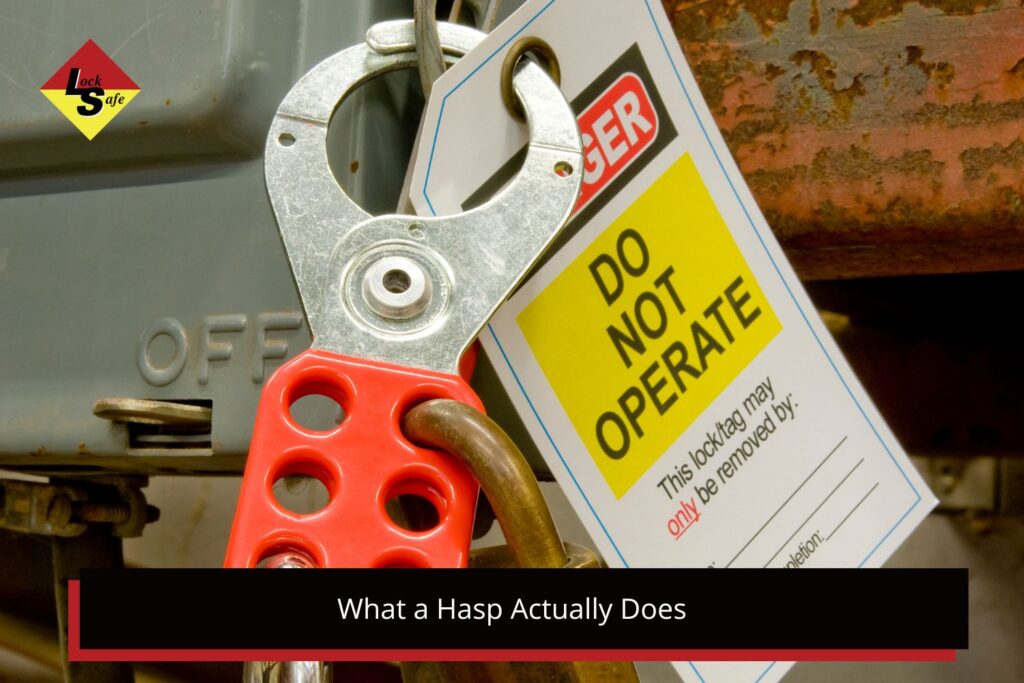

What a Hasp Actually Does

Hasps are used in LOTO procedures to isolate power sources when more than one worker is involved. Each person adds their own padlock to the hasp, ensuring no one can remove the device until all locks are cleared.

This design prevents any chance of the machine starting while maintenance is underway. Everyone’s safety is tied to their individual lock. The device won’t restart unless every worker confirms the job is done.

Hasps also show how many people are working. It’s a clear visual signal that maintenance is active. If someone sees only one lock, they might wrongly assume it’s safe to restart equipment. Hasps avoid this by making the situation obvious.

Every person involved gets the same level of protection. Skipping this device removes that layer of control, which increases the risk of error or accident.

What Happens When Hasps Are Skipped

Some workers think skipping a hasp saves time. In reality, it adds risk. If one person locks out a machine but others don’t, it creates false confidence that the job is safe.

When a hasp isn’t used, others might not know someone is still working. That means a machine could be turned on while someone is inside or handling moving parts. These incidents cause serious harm, from crush injuries to electrocution.

There’s also the issue of responsibility. The hasp gives each worker control over their safety. Without it, individual accountability disappears.

Finally, compliance matters. In Australia, Safe Work rules require full LOTO processes. If someone skips steps and an incident happens, the company could face heavy fines or legal action.

Skipping hasps isn’t a time-saver. It’s a shortcut to major risks, injuries, and long-term consequences.

How to Handle Maintenance Under Pressure

Emergencies need fast action, but safety should not be sacrificed. There are ways to handle urgent jobs while still using full LOTO procedures.

Start with preparation. Make sure all necessary lockout tools, including spare hasps, are available and ready to use. There should never be a shortage of equipment.

Workers must also be trained to treat every step as essential. Hasps are not optional. Teams need to understand why each piece matters and how skipping one part weakens the entire process.

Good communication helps too. Everyone on the team should confirm when the lockout is applied, and nobody should begin work until every lock is in place.

A strong safety culture means empowering anyone to speak up. If someone sees a step skipped, they should be able to stop the job without fear.

Leaders must lead by example — urgent work still needs full compliance.

Always Use Hasps — No Exceptions

Hasps are not optional. They are a critical part of every lockout process that protects everyone involved. Skipping them, even once, puts lives at risk.

Locksafe supplies industrial-grade hasps, padlocks, and lockout gear that meet Australian safety standards. Our products support safe maintenance and compliance across all types of worksites.

If your team works under pressure, proper equipment and systems are essential. Make sure nothing is missed.

Contact us to get the right gear and keep every LOTO procedure safe and complete.