Lockout Tagout (LOTO) systems are vital in high-risk worksites, but many boards are poorly placed or overlooked during setup. When boards are hidden, disorganised, or positioned too far from equipment, workers face delays during shutdowns. These gaps increase the chance of shortcuts being taken, leaving people exposed to serious hazards.

Industries such as mining, utilities, and manufacturing often struggle with LOTO stations that do not reflect the way isolation tasks are carried out. A station set up without considering workflow, visibility, or accessibility can quickly become a safety risk instead of a safeguard.

The solution is to install boards that match site-specific needs and provide fast access during emergencies. Correct placement, durable materials, and regular inspections help maintain compliance while reducing downtime.

This guide explains the essential steps for setting up boards in high-risk zones and highlights the types of systems available to support safe and efficient isolations.

What Is a Lockout Tagout Station?

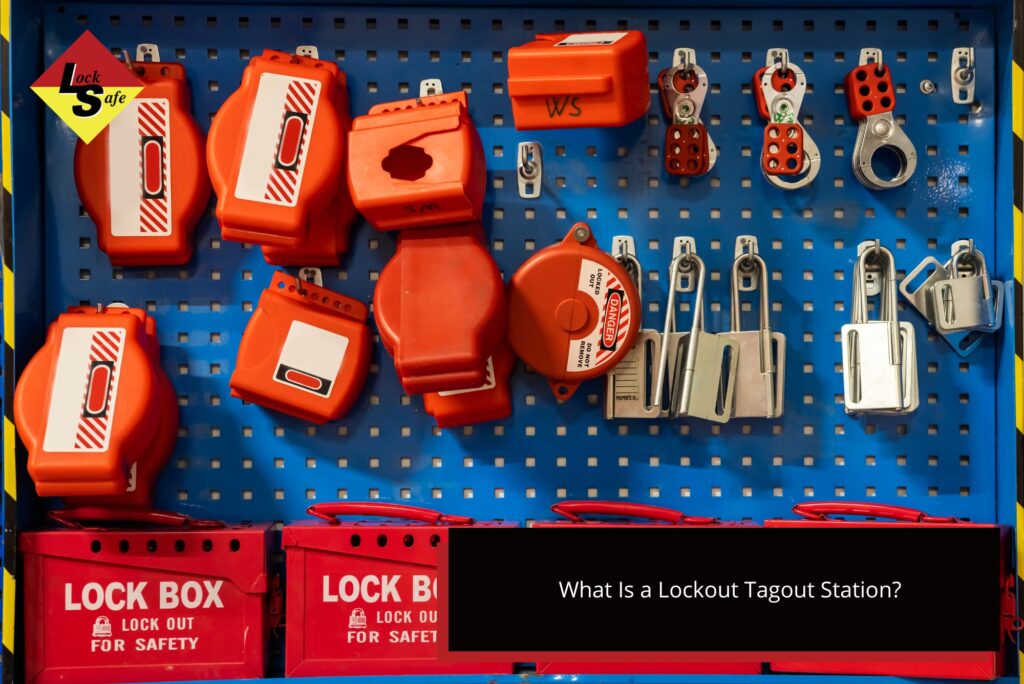

A lockout tagout (LOTO) station is a central point where isolation equipment is stored in an organised and accessible way. These stations hold items such as padlocks, tags, hasps, and lockout devices for switches, plugs, and valves. Having everything in one location ensures workers can find and return equipment without delay.

The main purpose of a LOTO station is to support compliance and improve site safety by keeping essential tools visible and ready for use. Stations should be set up so only authorised personnel can access the equipment, reducing the chance of misuse or missing items. Properly designed boards make it easier for teams to follow isolation procedures, even during urgent shutdowns.

Different setups exist depending on the worksite. Some stations are fixed to walls in workshops or switch rooms, while others are portable for technicians who move between jobs. The choice depends on the type of machinery, the work environment, and how frequently isolations occur.

No matter the design, the priority is that every worker can quickly reach the tools they need to complete lockout procedures safely.

Choose the Right Location

The placement of a lockout tagout board determines how effective it is in supporting safe isolation. If a board is hidden behind equipment, blocked with storage, or placed too far from isolators, workers may avoid using it during urgent shutdowns. In high-risk areas this can lead to unsafe shortcuts and greater exposure to hazards.

A suitable location is one that is clearly visible, easy to reach, and not obstructed. Boards should never sit in the direct line of hazards such as moving machinery, hot surfaces, or areas where vehicle traffic is constant. Instead, they should be positioned close enough to isolators to allow fast access while still maintaining a safe buffer from risk zones.

Larger sites often require multiple boards to support different work zones. A processing facility may install wall mounted systems near production areas, while mobile operations often rely on smaller portable setups. Matching placement to site activity ensures workers always have isolation equipment within reach without needing to leave the job area.

Image cue: Lockout board positioned beside a production line

Keep It Organised and Labelled

A lockout tagout board must remain orderly so workers can locate and return items without delay. When equipment is misplaced or mixed together, time is wasted, and isolation procedures may be ignored. Organisation reduces this risk by keeping every tool visible and accessible.

Each board should have a dedicated position for common equipment. Items typically stored include

- padlocks

- tags

- hasps

- lockout devices for switches, valves, and plugs

Using labelled hooks, trays, or holders ensures tools are collected and returned to the same spot after use. This reduces the chance of missing items and speeds up isolations during urgent shutdowns.

Clear organisation also supports inspections. Supervisors can instantly see if gear is missing, damaged, or in the wrong place. Workers of all experience levels benefit from a simple layout, as they can identify what they need without instruction. Maintaining a consistent structure improves accountability and helps the site comply with safety requirements.

Use Durable, Site-Ready Materials

Lockout tagout boards are often exposed to harsh site conditions. If the materials are not durable, equipment can be damaged, labels may fade, and boards can lose their effectiveness. Choosing the right build ensures the station continues to function even under constant use.

Boards in high-risk zones should withstand heat, dust, moisture, and vibration from nearby machinery. Outdoor locations also require resistance to UV exposure and weather conditions. Stainless steel frames with powder-coated finishes are commonly used in industrial sites because they provide strength and corrosion resistance. Polycarbonate panels may also be suitable in areas where visibility and lighter weight are priorities.

For portable setups, rugged carry cases with internal mounting panels are often preferred. These allow technicians to transport lockout gear safely across different work areas. A poorly built or lightweight option may seem cost effective but will not last in environments where equipment is handled daily.

Selecting strong, site-ready materials helps reduce downtime caused through broken or missing tools. It also ensures the board remains compliant and practical for long-term use in demanding worksites.

Secure the Area

Lockout equipment must be accessible to authorised workers but protected from tampering or misuse. If a board is left unsecured in a busy site, tools can be removed, misplaced, or used without proper authority. This not only creates compliance issues but also increases the risk of isolation procedures being bypassed.

In shared or contractor-heavy worksites, lockable cabinets or enclosed stations are often the most effective option. They keep equipment visible while ensuring only trained staff can access it. Cabinets can be fitted with keyed locks, combination systems, or latch locks depending on site needs. Transparent doors are often preferred, as they allow supervisors to visually confirm the availability of gear without opening the cabinet.

Securing the station also helps with accountability. When equipment is kept in a controlled space, it is easier to track usage and identify if items are missing. This improves confidence in the lockout system and reduces delays during inspections or audits.

The right level of security should match the environment. High-traffic zones may require enclosed cabinets, while controlled workshops can operate effectively with open boards.

Maintain and Audit Regularly

Installing a lockout tagout board is not a one-time task. Without regular checks, equipment can go missing, labels may fade, or access points can become blocked. Routine inspections are essential to ensure the station continues to support safe isolation procedures.

Audits should look for missing or damaged items, unreadable tags, and incorrect placement of tools. Supervisors should also confirm that access to the board is clear and not obstructed with vehicles, storage, or machinery. A record of these inspections should remain part of the site’s WHS documentation.

A small buffer stock of common items such as padlocks, tags, and hasps should be kept close to the board. This allows quick replacement of gear without delaying isolation work. Workers should also be reminded to return equipment immediately after use, which maintains accountability across the site.

When inspections form part of routine safety checks, boards stay reliable and ready for emergencies. Consistent auditing identifies issues before they compromise safety and ensures compliance with workplace standards.

Match the Setup to the Worksite

No two worksites operate under the same conditions, so lockout tagout boards must reflect the environment where they are used. A board that works well in a fixed processing line may not be suitable for mobile teams working across multiple locations. Matching the setup to site requirements ensures isolation procedures remain practical and effective.

On large industrial sites, multiple boards may be needed across zones to reduce travel time and improve access during urgent shutdowns. For example, a plant may install wall mounted systems near production areas, while a maintenance crew working on mobile rigs may rely on a portable lockout station. Custom or modular designs are also useful when equipment changes frequently or when space limitations require a flexible layout.

The frequency of isolations, the number of workers involved, and the type of machinery should all influence the design. A setup that aligns with site activity reduces the risk of tools going unused or ignored. The goal is always to provide equipment that is visible, accessible, and reliable for the specific conditions of the worksite.

Types of Lockout Boards

Lockout tagout boards come in different styles, each designed for specific site conditions. The right choice depends on how isolations are carried out and whether the work is fixed or mobile.

Main options include

- wall mounted boards for workshops and switch rooms

- portable boards for crews moving between sites

- cabinet style stations that protect equipment from dust and moisture

- group lockout boxes for team isolations

Custom or modular boards may also be required when layouts change or when specialised tools need storage. Selecting the right type ensures equipment is always accessible and suited to site conditions.

Need Help Choosing a Lockout Station?

Installing and maintaining the right lockout station is an essential step in keeping high-risk sites safe. Whether the setup requires wall mounted systems for fixed equipment or cabinet style stations in high-traffic areas, the goal remains the same—quick access to reliable gear stored in an organised and secure way.

Locksafe provides a full range of solutions designed to support compliance and safe isolation practices. From compact portable kits to larger cabinet style stations, the focus is on reliable performance and worker safety.

Contact the team on 08 9455 7255 for advice on the most suitable system for your site.