A lock left behind during a lockout tagout procedure might seem like a small oversight. But the impact can be serious and immediate. Workers may be exposed to unexpected startup, equipment can be damaged, and your site can be shut down due to non-compliance. In many industries, a single missed lock can mean the difference between a safe restart and a critical incident.

This article explains the right way to manage forgotten locks, reduce risk, and improve site safety. The information here is designed to support safety managers, technicians, and supervisors working under Australia’s lockout tagout rules.

Why a Forgotten Lock Is a Serious Issue

Lockout tagout is designed to keep energy sources isolated until work is fully completed. That includes mechanical, electrical, hydraulic, and pneumatic systems. If someone forgets to remove their lock and another worker or team restores the system, serious injury can occur. A piece of machinery might start while someone is still in a danger zone.

In Australian worksites, from power stations to processing plants, these kinds of errors have led to legal action and long shutdowns. Safe Work Australia enforces strict lockout rules under WHS legislation. Companies can face major penalties if found to be negligent, even if no injury occurs. When a forgotten lock delays equipment restart, it also causes loss in productivity, increased downtime, and repair costs—especially if the equipment was force-started.

Common Reasons Why Locks Are Forgotten

Mistakes happen even on well-managed sites. But understanding the root causes of forgotten locks helps reduce how often they occur. One of the most common triggers is shift rotation. When one team finishes and another takes over, a lock may be left in place without notice. If the original worker fails to communicate clearly, no one knows the lock is still active.

Other reasons include distraction during cleanup, unclear lockout instructions, or using tags without proper identification. In fast-paced worksites, pressure to finish jobs quickly can lead workers to skip steps. Even experienced staff might forget to remove their own lock when rushing to assist others.

In many cases, the issue is not about the worker being careless—it’s about the process being too reliant on memory. Without a system in place that forces each step to be double-checked, even small errors become likely.

Prevention Steps That Work

The most effective way to handle a forgotten lock is to stop it from happening in the first place. Prevention tools can be simple but powerful. When built into the daily routine, they reduce risk and help build a consistent safety habit across all teams.

Use Visual Tools and Checklists

Every lockout point should include a checklist that confirms steps like isolation, lock placement, and lock removal. Laminated cards, wall-mounted signs, and colour-coded slots help remind teams what’s been done and what hasn’t. Some sites also use shadow boards where locks are returned to specific locations after each job. When a lock is missing from the board, it’s a visible prompt to follow up.

These visual cues remove the need to rely on memory. Workers no longer have to guess whether something was done—they can see it.

Create Peer Check Systems

Lockout tagout should not rely on one person’s memory alone. A second set of eyes provides both safety and accountability. By assigning peer checks at the end of each task, workers are encouraged to take shared responsibility. This means that once work is complete, a team member must verify that all locks are removed before re-energising the system.

In some sites, this is done through a simple verbal confirmation. In others, a formal sign-off sheet requires initials from both the person removing the lock and the peer reviewer. The benefit is twofold. It confirms the system is clear and safe for use, and it builds a work culture where looking out for one another is expected.

This system is especially useful during shift changes. If one team signs off before the next team starts, any lock left in place can be caught early. That reduces handover confusion and keeps downtime to a minimum.

Choose Equipment That Shows Ownership

Clear ownership of each lock is key to a safe and smooth lockout tagout system. Locks that are identical or unlabelled make it harder to know who is responsible for removal. Using locks with built-in identification features reduces this risk.

Locksafe manufactures gear specifically designed for Australian worksites. Our locks include space for ID labels and are colour-coded to match departments or roles. Hasps are built with numbered slots, so each person’s lock position is tracked and easy to verify.

When gear clearly shows who placed it, it becomes easier to track progress, confirm completion, and reduce the chance of someone walking away without removing their lock. Combined with visual lockout stations, this level of traceability gives supervisors a clear overview at a glance.

What To Do If a Lock Is Left on the Hasp

Even the best-prepared sites can experience a missed step. When a lock remains on a hasp after work is done, the response must follow a safe, authorised process. Rushing or bypassing this step risks damage, injury, or legal action.

First Step — Re-isolate the Machine

Never assume the remaining lock means full isolation. Instead, apply a backup lockout method immediately. This might include shutting off the main breaker, applying another lock at the energy source, or attaching a secondary padlock to the same hasp. The goal is to ensure the equipment stays off while the forgotten lock is addressed.

This protects everyone, especially if someone unknowingly tries to restart the machine during this time.

Next Step — Find Out Who Owns the Lock

Use the lock’s tag, ID sticker, or number to identify the person who applied it. If that information is missing, use a shift log or consult the supervisor for that task area. Many sites also track lock assignments through a digital board or paper log that records each lock and user.

The faster the owner is found, the quicker the site can move forward with safe resolution.

Contact the Worker

The ideal case is when the worker who placed the lock is still on-site. They can return to the machine, verify that their task is complete, and remove the lock personally.

If the person is no longer available—due to a shift change or emergency—then a senior, authorised person must step in. That individual must confirm that the system is fully isolated and that removing the lock will not expose anyone to risk. This decision should never be made alone and must follow your internal procedures for override approvals.

Record the Whole Event

Every action taken during a forgotten lock event should be documented clearly. This includes who discovered the issue, how the equipment was isolated, who was contacted, and who approved any lock removal. This record acts as protection for both the business and the workers. It also ensures that the site can learn from the event.

Documentation should include time stamps, names, photos if applicable, and a full description of each step taken. Use your site’s official incident log or create a standard lock removal form. These records can be used for internal safety reviews, compliance audits, and insurance assessments.

Keeping this data consistent, trends can be tracked. If lockouts are being left on specific machines more often than others, that pattern can guide improvements.

Final Check Before Restarting

After the forgotten lock has been safely removed, do not rush into restarting the system. First, complete a full walkaround of the equipment. Check that all tools and materials have been cleared from the area. Look over mechanical and electrical components to ensure nothing was damaged during the delay.

Then review the original lockout checklist again. If all steps are confirmed and no other locks remain, the authorised person can approve the restart. This double-check confirms that isolation is fully removed and that it’s safe to bring the equipment back online.

Skipping this step can lead to restart problems, from jammed motors to overlooked safety hazards. Take the time to get it right. A safe return to service reduces rework and protects everyone on-site.

Review and Fix the Root Problem

Once the incident is resolved, the next priority is to stop it from happening again. This doesn’t mean pointing fingers—it means looking at the process and where it fell short. Every forgotten lock is a sign that something in the system can be improved.

Start with a short debrief. Meet with the worker involved, the supervisor, and the safety officer. Go through what happened in detail. Ask what part of the process caused confusion, what could have helped them remember, and whether the equipment or signage played a role.

Next, check whether training materials reflect current procedures. If steps are outdated or unclear, workers are more likely to make mistakes. Training should not be a one-time event. Ongoing refreshers, toolbox talks, and practical walkthroughs help keep safety fresh in everyone’s mind.

Then assess broader issues. Was the worker under pressure to finish fast? Was there clear peer oversight? Were the LOTO tools easy to use? Did the shift handover include a checklist?

Based on this review, make changes that strengthen the system. These may include

- Adding visual lock tracking boards

- Installing clearer signage at lockout stations

- Introducing peer check requirements

- Increasing access to hands-on training

- Creating digital lock tracking tools or ID logs

A Missed Lock Can Cause Bigger Issues

Leaving a lock behind affects more than one task. It shows that something in the process failed—communication, awareness, tools, or supervision. If that gap is not closed, the risk stays open.

Workers may begin to lose confidence in the lockout process. That creates hesitation, miscommunication, and shortcuts. Over time, small lapses turn into larger safety failures. Rebuilding that trust means showing that every step matters, including how you respond when something goes wrong.

From a business view, lockout errors are often reviewed during audits. Insurance providers and regulators assess how often these errors occur and whether the site follows clear, approved protocols to correct them.

Taking proactive steps after each mistake strengthens your overall safety posture and helps prove that your site is managing risk, not ignoring it.

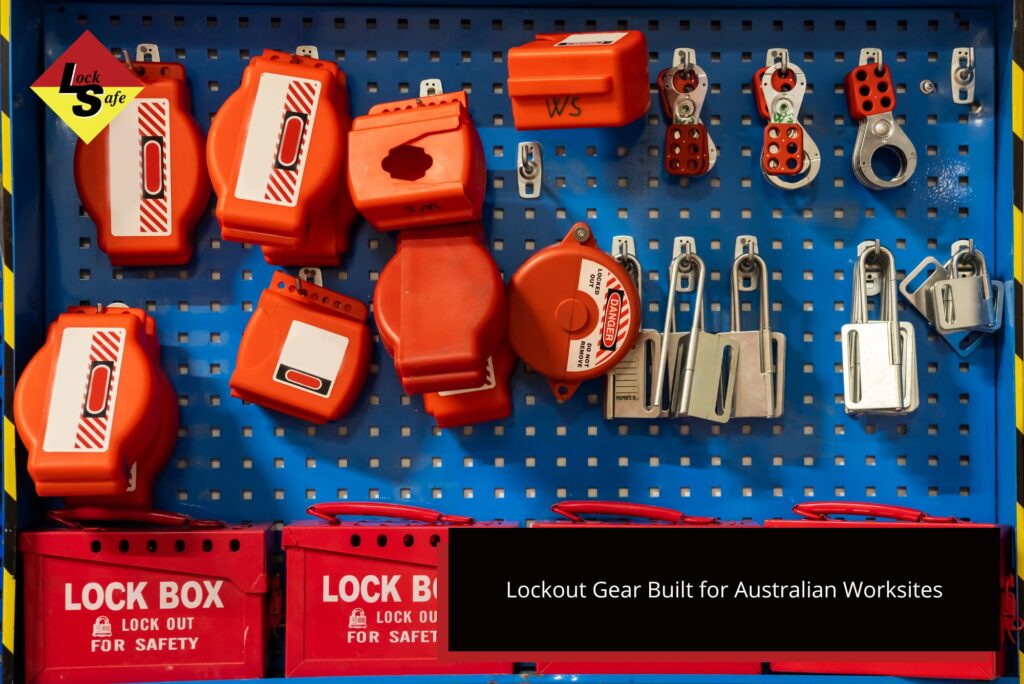

Lockout Gear Built for Australian Worksites

Using the right tools is just as important as having the right process. Locksafe manufactures a full range of lockout tagout gear suited to local site conditions. Our equipment is designed with clear identification, strong materials, and user-friendly features to support long-term safety.

We offer:

- Multi-lock hasps for group isolation

- High-visibility padlocks with custom ID options

- Lockout boards for tool tracking and return

- Lockout boxes for shift-based control

- Training signage and checklist boards

Every product is tested for Australian work environments—heat, dust, vibration, and outdoor use. This ensures your equipment holds up under real worksite pressure.

We also offer guidance on how to set up your system from scratch. Whether you’re upgrading gear or reviewing your entire lockout plan, our team works with you to match the tools to your needs.

Talk to Us

If your site has experienced issues with lock removal, or you want to improve how your team handles isolation, Locksafe can help. We supply gear and guidance to help prevent forgotten locks, reduce downtime, and protect workers.

Our gear supports full compliance with WHS guidelines and is backed by field-tested durability. We also run training sessions and walkthroughs to help you set up a working lockout system that fits your operation.

Contact Locksafe

Phone — +61 (0)8 9455 7255

Email — info@locksafe.com.au

FAQs

Can someone else remove a lock if the worker is gone?

Only if a senior authorised person completes full isolation checks and signs off the action. This must be documented clearly before removal.

Is it legal to cut off a lock?

It is not legal unless it follows your site’s formal override process. Unapproved lock removal is a serious breach of safety rules.

How can I reduce lock errors during shift changes?

Use a lock box and assign sign-in and sign-out control to a supervisor. Ensure each shift reviews the lockout board before restarting equipment.

Do you offer lock boards or ID-based tracking gear?

Yes. Our products include full LOTO boards with lock slots, worker ID tags, and checklist panels for visual tracking.

Can lockout mistakes affect my insurance?

Yes. Repeated safety lapses can impact premiums and claims. Insurers often review lockout procedures during risk assessments.

What is the best way to train staff on lockout mistakes?

Provide real-world examples, short refresher talks, and on-site practice using actual lockout gear. Visual demos are more effective than slideshows.