Working on powered machinery without cutting off the energy supply can lead to electric shock, mechanical injury, or unexpected start-up. These risks occur in mining, construction, manufacturing, and heavy transport, where systems run at higher voltages and currents.

Incidents often happen during maintenance or inspection when energy is not fully isolated. If disconnection steps are missed, hazardous energy can remain in conductors, control circuits, or stored devices, increasing the chance of harm and equipment damage.

Isolation switches are installed to remove electrical energy from equipment before work begins. They are placed where operators can access them, labelled for the controlled circuit, and selected to match system ratings. In many workplaces, they form part of lockout and tagout so that once set to off, the device can be secured and identified. Using the correct device and procedure reduces exposure to energised parts and supports WHS obligations.

What Is an Isolator Switch

An isolator switch is a manual device that opens a circuit so no current can pass to downstream equipment. It is intended for off-load operation and provides a fixed open state for safe access to machinery or conductors.

This device is different from a circuit breaker. A breaker interrupts fault or overload current and provides protection; an isolator is used after the circuit is made safe to ensure separation. In practice, the isolator is operated first for shutdowns that do not involve fault clearing, or after protective devices have removed load.

Typical forms include rotary and lever mechanisms, with enclosed versions for harsh environments. Selection is based on voltage, continuous current, utilisation category, and installation location. Many models include a hasp or provision for a padlock to support lockout and tagout.

Installation must align with AS/NZS 3000 for placement, labelling, and conductor terminations, and the device must be maintained on a set schedule to keep contacts and mechanisms in working order.

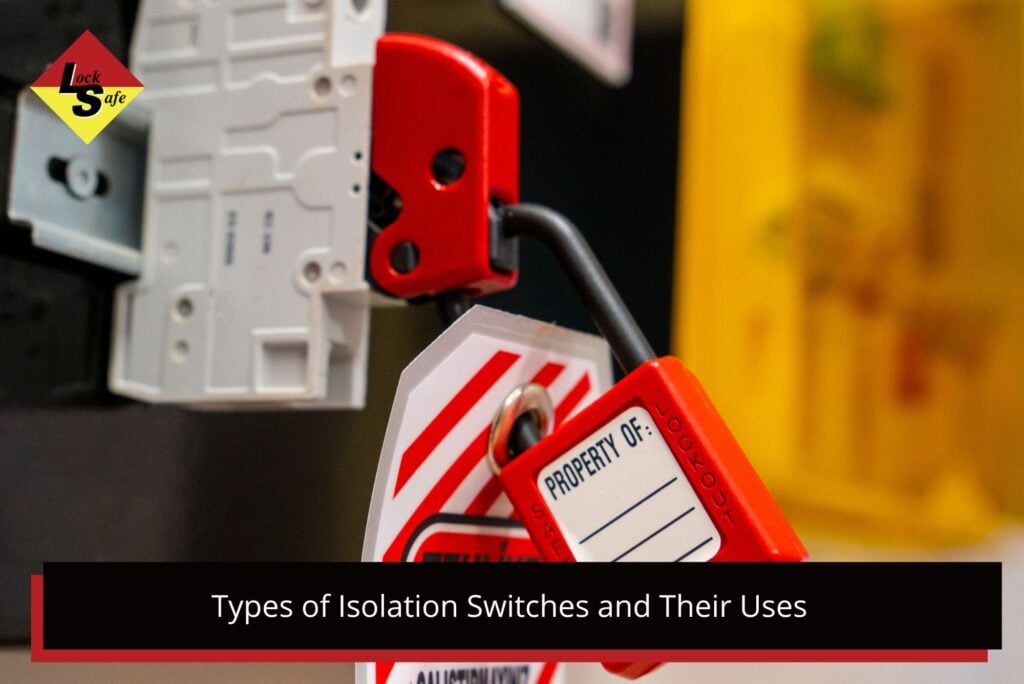

Types of Isolation Switches and Their Uses

Isolation switches disconnect machinery or electrical systems from the power source during servicing or an emergency. In many workplaces they form the first step in a lockout process.

Common types include:

- Starter isolator switch

- Battery isolator switch

A battery isolator switch sits between the battery and the electrical system. Switching it off stops current from reaching controls and motors. It is used on mobile plant, mining vehicles, and marine equipment to prevent unintended activation and to allow safe checks when equipment is idle.

A starter isolator switch is installed in the starter circuit. Switching it off stops the engine from cranking while maintenance is carried out. It can allow non-drive functions such as lighting or monitoring to remain powered for testing without enabling the engine.

Selection should match voltage and current rating, environmental protection, and access needs. Correct placement and clear labelling help operators use the device quickly and verify the circuit is open before work begins.

How Isolation Switches Work

An isolation switch functions by creating a visible break in the electrical circuit, stopping current from flowing to connected equipment. This is achieved by physically separating the internal contacts, ensuring the circuit remains open until the switch is returned to the on position.

Most designs are manually operated and clearly indicate when they are in the off position, allowing workers to confirm that the power supply has been disconnected. In many industrial applications, switches include a locking provision so they can be secured as part of a lockout procedure to prevent accidental reconnection.

Every unit is rated for a specific voltage and current to suit the system it controls. Underrated devices can overheat or fail, so correct selection is critical. Installation should position the switch for easy access, apply clear labelling, and meet AS/NZS 3000 requirements.

For maximum safety, operation of the switch must be paired with procedures that verify no residual or stored energy remains in the system before any work begins.

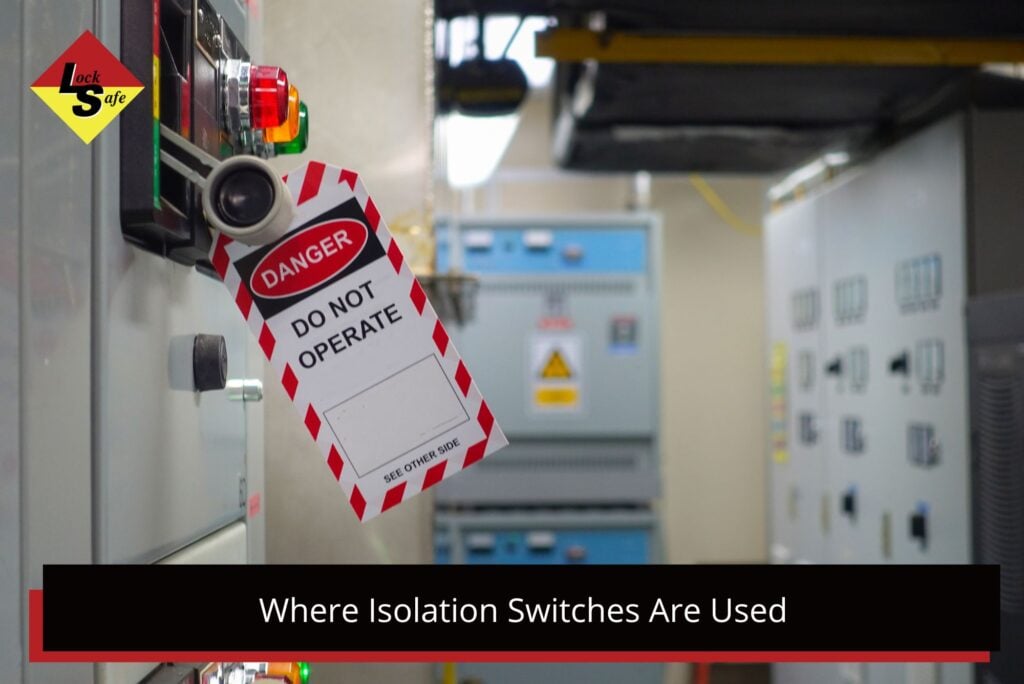

Where Isolation Switches Are Used

Isolation switches are installed across a wide range of industries to control hazardous energy during maintenance, inspections, and emergency shutdowns. Their use is most common in environments where machinery operates under high electrical loads or presents significant mechanical hazards.

In the mining sector, isolation switches are fitted to haul trucks, conveyors, crushers, and processing equipment to allow safe servicing in high-risk areas. Construction sites use them on mobile plant and fixed installations to prevent unplanned activation during repair work. In manufacturing, they are integrated into production lines, CNC machines, and other powered equipment to ensure compliance with safety procedures.

Marine and transport industries rely on isolation switches for both safety and battery preservation, allowing operators to cut power when vessels or vehicles are idle. Agricultural operations use them on harvesting machinery and pumps to reduce the risk of injury when working near moving components.

Regardless of industry, placement of the switch is critical — it must be accessible, clearly labelled, and tested regularly to ensure it functions as intended.

Safety Standards and Compliance in Australia

Isolation switches in Australia must meet strict safety and performance requirements to ensure they operate reliably under all site conditions. The AS/NZS 3000 Wiring Rules outline installation, accessibility, and labelling standards, while the Work Health and Safety (WHS) Regulations require hazardous energy to be controlled during servicing and maintenance.

Switches must be rated for the maximum voltage and current of the circuit, provide adequate contact separation to prevent arcing, and be installed in accessible, clearly marked positions. In most workplaces, they are integrated into lockout/tagout systems, with secure locking points and tags to prevent unauthorised reconnection.

Regular inspection is a compliance obligation, not an optional step. Employers must follow manufacturer-recommended intervals or documented maintenance schedules to confirm mechanical integrity, verify clean and undamaged contacts, and ensure the switch opens and closes the circuit correctly. Any fault or wear must be rectified immediately to maintain operational safety and legal compliance.

Failure to meet these requirements can lead to WHS breaches, fines, downtime, and increased injury risk.

Safe Use Procedures

Correct use of isolation switches is essential for controlling hazardous energy and preventing workplace incidents. Before starting any maintenance or inspection, machinery must be fully shut down and isolated from its power source.

The general procedure includes:

- Stop the equipment using normal operating controls.

- Identify all energy sources, including electrical, hydraulic, and pneumatic systems.

- Operate the isolation switch to disconnect electrical supply.

- Apply a lockout device to the switch where required.

- Attach a clearly marked tag with the name and date of the person performing the isolation.

- Test to confirm no residual energy remains before commencing work.

Only the person who applied the lock and tag, or an authorised supervisor, should remove them. If the equipment is out of service, an “out of service” tag must remain in place until it is safe to operate.

Following these steps ensures compliance with workplace safety regulations and reduces the risk of accidental re-energisation.

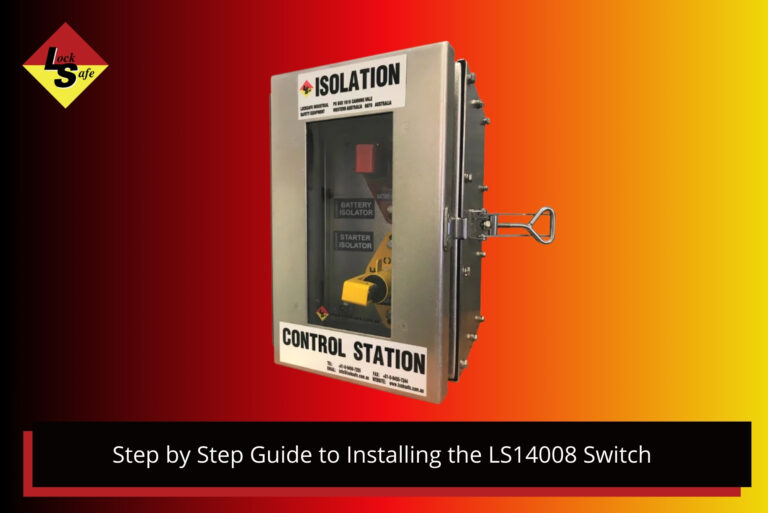

Get Compliant Isolation Switch Solutions

Locksafe supplies a wide range of isolation switches and lockout devices designed for Australian worksites. Our products meet AS/NZS 3000 Wiring Rules and are built to perform in demanding industrial environments. Whether you need starter isolator switches, battery isolator switches, or protective isolation cabinets, our team can help you select and install the right equipment for your operations.

For advice or to arrange supply, contact us on (08) 9455 7255. We can provide compliant solutions that support your workplace safety procedures and meet WHS requirements.

FAQs

What is the difference between an isolator and a circuit breaker?

Are isolators mandatory in Australian workplaces?

How often should these devices be checked?

Can one isolator control multiple machines?

Do isolators control non-electrical energy sources?