Incorrectly mounted lockout tagout (LOTO) stations can compromise worker safety and cause noncompliance with Australian Work Health and Safety (WHS) laws. Poor placement, weak materials, and irregular inspections often reduce reliability during maintenance and shutdowns. These issues increase the risk of incomplete isolation and on-site incidents.

Under WHS regulations, machinery must include isolation points that can be locked and remain functional. A well-mounted LOTO station allows workers to isolate energy quickly, maintain control during servicing, and support audit requirements under AS/NZS 4836:2011. Correct installation also helps standardise safety procedures across different work areas.

Knowing where most mounting errors occur gives teams the chance to improve installation practices and strengthen compliance. Each of the points below outlines a specific problem and the practical steps to fix it.

1. Placing the Station Too Far from Isolation Points

When a LOTO station is placed far from the machinery it serves, workers waste time walking back and forth for locks or tags. This extra distance often leads to skipped steps and reduced compliance during shutdowns.

A correctly placed station should always be within clear view or a short walk from the isolation point while remaining outside the hazard zone. Large facilities may need multiple stations to cover wider areas efficiently.

Key placement tips:

- Keep each board within sight of the equipment.

- Ensure walkways remain clear at all times.

- Inspect accessibility regularly during safety audits.

These adjustments make isolations faster, safer, and easier to complete without shortcuts.

2. Incorrect Mounting Height and Ergonomics

Improper mounting height or awkward positioning can make LOTO gear difficult to reach. If workers must stretch, bend, or reach behind equipment, they’re less likely to return items properly after use.

Mount the station between 1.2 m and 1.5 m from the floor. This height suits most users and meets general ergonomic guidelines. Avoid placing boards behind doors, panels, or pipes that block access. In narrow spaces, consider swing-out or drop-front designs that provide clearance without restricting visibility.

To improve ergonomics:

- Standardise mounting height across all stations.

- Use wall brackets that prevent vibration or slippage.

- Keep tag documentation holders within reach.

Proper ergonomic setup encourages frequent use, reduces strain, and improves long-term compliance with lockout procedures.

3. Using Weak or Unsuitable Materials

Boards made from low-grade plastic or thin metal can corrode or crack under tough industrial conditions. Once surfaces fade or labels peel off, workers lose confidence in the station’s reliability.

Choose durable materials that can withstand humidity, dust, and temperature changes. Stainless steel and powder-coated metal offer strong resistance to corrosion and impact damage. Always seal cabinets to prevent water or debris from entering.

Best practices for durability:

- Use corrosion-resistant hinges and UV-protected finishes.

- For coastal or outdoor environments, use sealed metal enclosures.

- Inspect coating and labelling during maintenance checks.

For durable, Australian-made options, browse our new product range designed for harsh worksites.

4. Allowing Uncontrolled Access or Tampering

Leaving boards open in shared areas invites unauthorised access or misuse. Missing locks, tags, or hasps weaken the entire lockout process and reduce accountability.

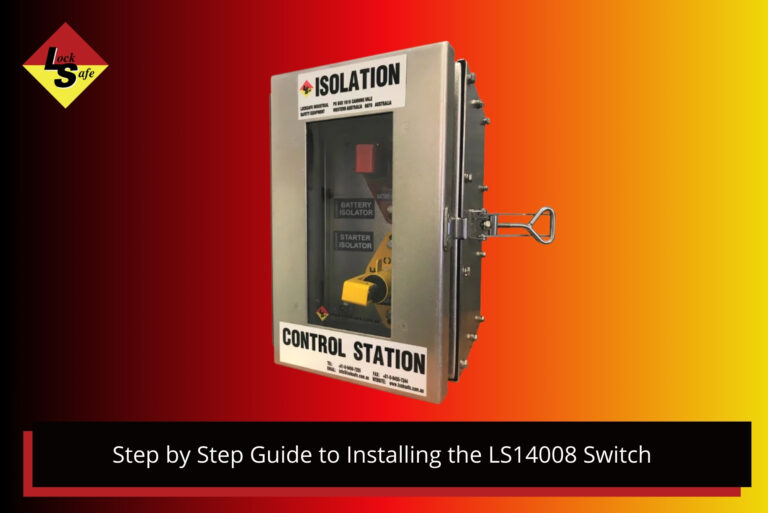

Install lockable cabinets or transparent-door enclosures in busy or contractor zones. This keeps the contents visible while preventing tampering. Access should be restricted to authorised and trained personnel only.

Security recommendations:

- Label each cabinet with responsible personnel or department.

- Maintain access logs for authorised users.

- Review access permissions after staff or contractor changes.

Our isolation cabinets provide reliable tamper resistance and quick visual checks of stored gear. Controlled access ensures that all devices stay secure and ready for use.

5. Disorganised or Inconsistent Layouts

A cluttered or inconsistent layout causes delays, confusion, and mistakes during isolation. Workers should instantly know where each tag, hasp, or lock belongs.

Create a structured layout with labelled hooks, trays, and shadow outlines for each item. Maintaining a consistent design across all stations helps workers identify missing gear quickly and promotes efficient audits.

Benefits of a standard layout:

- Speeds up isolation and reset procedures.

- Simplifies training for new workers.

- Reduces risk of leaving out essential lockout tools.

Shadow boards are especially effective for multi-station sites, allowing supervisors to check completeness at a glance. Consistent organisation supports accuracy and safe isolation routines.

6. Skipping Routine Inspections

Even the best station will fail without regular inspection. Missing padlocks, broken components, or faded labels often go unnoticed until a shutdown occurs. A neglected board undermines safety and breaches WHS duties.

Include every LOTO station in your scheduled audit plan. High-use areas should be checked weekly; others can be reviewed monthly. Replace damaged items immediately and keep spare locks and tags nearby.

Inspection checklist:

- Verify all hooks and trays contain required items.

- Check for fading, rust, or loose parts.

- Record findings and assign follow-up actions.

Logging each inspection improves accountability and helps identify recurring issues before they compromise worker safety.

7. Using Generic Boards Instead of Site-Specific Designs

Generic boards often fail to meet site needs. A board suited for indoor offices may not perform well in outdoor or mobile environments. Using the wrong configuration can lead to poor usability and unsafe setups.

Design LOTO stations to match the workflow, environmental conditions, and frequency of maintenance. For outdoor areas, choose weather-sealed cabinets. Mobile or shutdown crews may need rugged, portable kits. Modular systems allow future expansion as plant layouts evolve.

Why site-specific design matters:

- Reduces installation errors.

- Matches how staff actually perform isolations.

- Improves compliance with AS/NZS 4836:2011 and AS 4024.1603.

These standards set clear expectations for machinery safety and prevention of unexpected startup, helping workplaces stay compliant.

Expert Lockout Solutions from Locksafe

Correctly mounted LOTO stations protect workers and improve compliance with Australian WHS laws. Locksafe designs and manufactures reliable lockout systems, isolation cabinets, and modular boards for industrial sites nationwide.

Our specialists can review your layout, recommend upgrades, and supply equipment built for harsh Australian conditions. Every system supports efficient energy isolation and long-term durability.

For expert advice, setup support, or to discuss site-specific configurations, contact Locksafe today.