Workers are injured when machines restart during servicing. This often happens when energy is not isolated or clearly marked. Uncontrolled energy can lead to electric shock, crushing, or burns.

Many sites rely on verbal checks or warning signs without using proper lockout or tagout devices. These steps are not enough. Equipment can still be switched on by mistake or restarted by another worker.

Lockout tagout uses two systems—physical locks and visible tags—to control energy. Lockout blocks energy flow. Tagout provides warnings. Each method plays a role in keeping equipment safe during repairs and maintenance.

What Lockout Devices Do

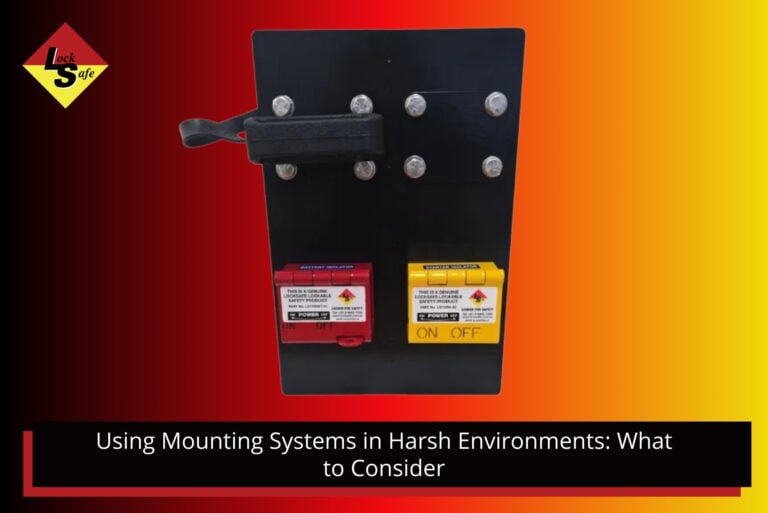

Lockout devices physically prevent machines from being powered on. They are attached to isolation points like switches, valves, or plugs to keep systems in a safe state. Workers apply a personal lock to ensure no one can remove it until the task is complete.

Common lockout products include:

- padlocks for circuit breakers and panels

- valve lockouts for pressurised lines

- plug lockouts for power tools or equipment

- hasps for shared lockout points

Each device ensures that energy stays off until every worker has removed their lock. This prevents accidental restarts and supports safe access during maintenance.

Why Lockout Devices Provide Better Safety

The main benefit of lockout is its physical barrier. Unlike tags, locks stop machines from being restarted by mistake. This is especially important in sites with rotating staff or high noise levels, where warnings can be missed.

Lockout systems reduce the chance of error and provide visible confirmation that equipment is isolated. They also support enforcement. If a machine has a lock with a worker’s name on it, it cannot be used until that person removes it. This lowers the risk of miscommunication between shifts and departments.

Workplaces that use lockout devices see fewer energy-related incidents. The system helps meet WHS standards and supports compliance inspections.

What Tagout Devices Are Used For

Tagout devices do not stop energy flow. Instead, they act as warnings. A tag is placed on an isolation point to show that the equipment is not safe to use. Tags often include the worker’s name, date, and reason for isolation.

These are useful when physical lockout is not possible due to the design of the machine. Tagout may also be used in low-risk tasks or as an added step alongside lockout for better visibility.

Effective tagout devices must be:

- durable under site conditions

- clear and easy to read

- standardised across the site

- used with formal procedures and training

Tagout Limitations and When to Avoid It

Tagout alone does not block equipment from restarting. It depends on workers noticing and following instructions. Tags can be ignored, removed, or misunderstood if training is weak or if the site has high staff turnover.

For this reason, tagout is not suitable as the only control on high-risk equipment. It may be used only when lockout is not practical and with added procedures to verify isolation.

WHS regulations often require a higher level of control than tagout provides. Lockout is the preferred method. Relying on tags alone may not meet legal standards and leaves room for human error.

Main Differences Between Lockout and Tagout

| Feature | Lockout Devices | Tagout Devices |

| Function | Physically prevent equipment operation | Warn others not to use equipment |

| Safety Control | Blocks energy release | Relies on warning and awareness |

| Equipment | Padlocks, hasps, covers | Tags with written details |

| Verification | Visible lock confirms isolation | Tag only shows warning, not isolation |

| Compliance Strength | Meets WHS preference for physical control | Acceptable only when lockout isn’t possible |

| Risk of Bypass | Very low if locks are used properly | Higher if tag is removed or ignored |

Lockout and tagout can be used together, but lockout offers stronger protection and is preferred where practical. Tags should never replace locks in high-risk areas.

Setting Up a Reliable Lockout Tagout System

A safe system must include more than just gear. Written procedures, training, and audits are required. Each isolation point must be mapped, steps documented, and all workers trained to apply locks and tags correctly.

Checklist for system setup:

- identify all energy sources

- use lockout where possible

- apply tags with clear warnings

- train both authorised and affected staff

- review and update procedures regularly

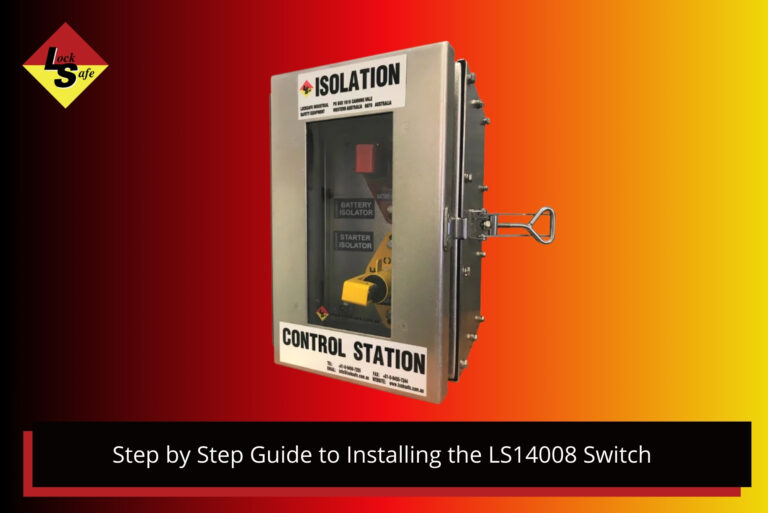

Our products meet Australian standards and cover a wide range of isolation needs, including electrical, valve, and plug lockouts. We support product selection, supply, and system setup across large or multi-site operations.

Lockout Tagout Supply and Support from Locksafe

Locksafe provides lockout tagout equipment built for Australian worksites. Our range includes valve lockouts, circuit breaker devices, group lock boxes, and tag stations. All products are designed for use in mining, manufacturing, and utility environments.

We handle setup, supply, and coordination for lockout systems across all site sizes. New or existing procedures can be aligned with WHS standards using reliable gear, clear signage, and site-specific isolation tools. Get in touch with us today!

FAQs

Is lockout always required in Australia?

WHS regulations recommend lockout where possible. Tagout alone may not meet requirements for high-risk plant or uncontrolled energy.

Can a tagout system be used for low-risk tasks?

Yes, but only with clear procedures and limited access. It should not be used on its own for complex or dangerous machinery.

What happens if someone removes another person’s tag?

Only the person who placed the tag should remove it. Removing someone else’s tag without following the procedure can lead to serious safety breaches.

How often should lockout gear be checked?

Gear should be inspected monthly and replaced if damaged. Logs should confirm usage, storage, and readiness.

Can one padlock be used by two workers?

No. Each worker must apply their own lock. Group hasps allow multiple locks at a single isolation point.